来源:知社学术圈

激光增材制造过程中微结构及其演化与制造参数之间关联的计算预测,已成为基于增材制造的材料/结构设计和开发过程的重要组成部分。选区激光烧结(SLS)增材制造过程中,微结构演化极度依赖于局部温度的急剧变化,故而常规的等温相场模型很难适用于SLS的模拟。

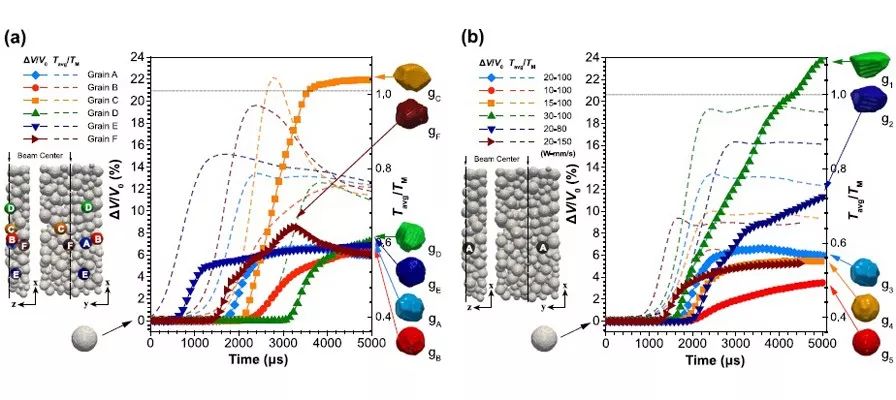

来自德国达姆施塔特工业大学的终身教授胥柏香领导的团队,与南京航空航天大学的青年千人易敏教授合作,建立了一种热力学自洽的非等温相场模型,用以研究SLS增材制造中微结构的演化。该模型考虑微结构与热传导的强耦合,SLS局部极高温导致的局部熔化,以及激光-粉末相互作用。并提出了一种类似于求解最小着色数问题的新解决方案,结合晶粒追踪方法,该方案可仅用8个序参量来模拟具有多达200个晶粒的系统。本研究还使用了基于LM算法的非线性优化方法,同时拟合模型与实验中表面能,晶界能随温度变化的趋势,以获取用于非恒温相场的模型参数。特别地,将该非等温相场模型用于SLS处理316L不锈钢粉末的研究,揭示了激光功率和扫描速度对孔隙率、表面形貌、温度分布、晶粒几何形状以及致密度等微观结构特征的影响规律,并证实了该模型可用于预测SLS过程中致密化因子与激光比能量之间的关联。该工作提出的非等温相场模型及其相关高效数值方法,有望用于SLS增材制造的大规模计算模拟。

该文近期发表于npj Computational Materials 5: 81 (2019),英文标题与摘要如下,点击左下角“阅读原文”可以自由获取论文PDF。

3D non-isothermal phase-field simulation of microstructure evolution during selective laser sintering

Yangyiwei Yang, Olav Ragnvaldsen, Yang Bai, Min Yi & Bai-Xiang Xu

During selective laser sintering (SLS), the microstructure evolution and local temperature variation interact mutually. Application of conventional isothermal sintering model is thereby insufficient to describe SLS. In this work, we construct our model from entropy level, and derive the non-isothermal kinetics for order parameters along with the heat transfer equation coupled with microstructure evolution. Influences from partial melting and laser-powder interaction are also addressed. We then perform 3D finite element non-isothermal phase-field simulations of the SLS single scan. To confront the high computation cost, we propose a novel algorithm analogy to minimum coloring problem and manage to simulate a system of 200 grains with grain tracking algorithm using as low as 8 non-conserved order parameters. Specifically, applying the model to SLS of the stainless steel 316L powder, we identify the influences of laser power and scan speed on microstructural features, including the porosity, surface morphology, temperature profile, grain geometry, and densification. We further validate the first-order kinetics of the transient porosity during densification, and demonstrate the applicability of the developed model in predicting the linkage of densification factor to the specific energy input during SLS.

来源:zhishexueshuquan 知社学术圈

原文链接:http://mp.weixin.qq.com/s?__biz=MzIwMjk1OTc2MA==&mid=2247499095&idx=2&sn=598e2ad278ca47fb63d28627e4183345&chksm=96d403a8a1a38abe3fe72a521ac08d03d8913f7135dc76128cb9a6112cde2bb4a7f739d9213e&scene=27#wechat_redirect

版权声明:除非特别注明,本站所载内容来源于互联网、微信公众号等公开渠道,不代表本站观点,仅供参考、交流、公益传播之目的。转载的稿件版权归原作者或机构所有,如有侵权,请联系删除。

电话:(010)86409582

邮箱:kejie@scimall.org.cn